Project brief:

The company is a German multinational fashion and lifestyle brands. It is an in-house organic textile manufacturer company headquartered in Düsseldorf.

Areas & Tasks of the Platform / Application

Each area is individually tailored to the internal processes. It's about:

- listing of orders from different shops / sales channels

- controlling - as the leading system – of payments- & order-status

- generation of delivery notes (incl. barcode) & invoices

- sending emails to customers + other automations

- accounting / DATEV-API

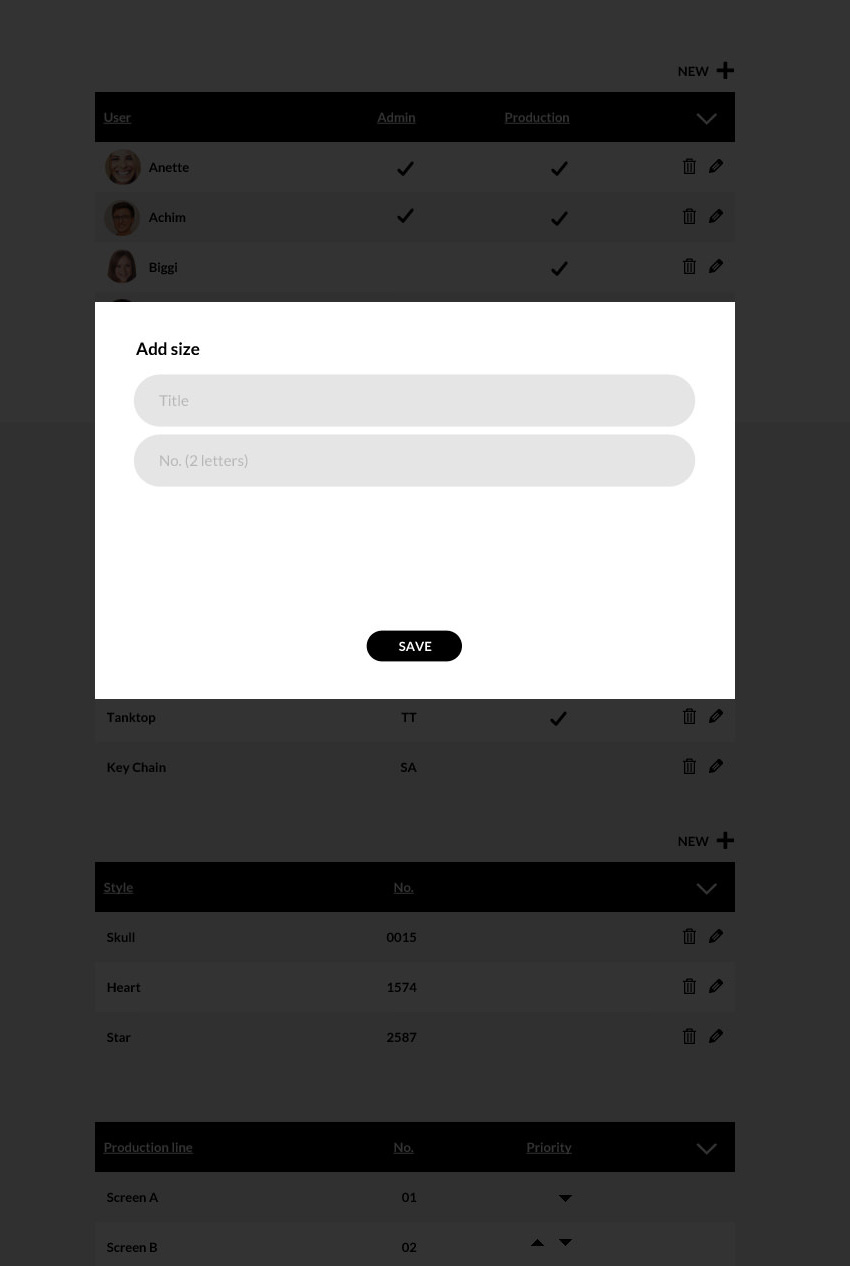

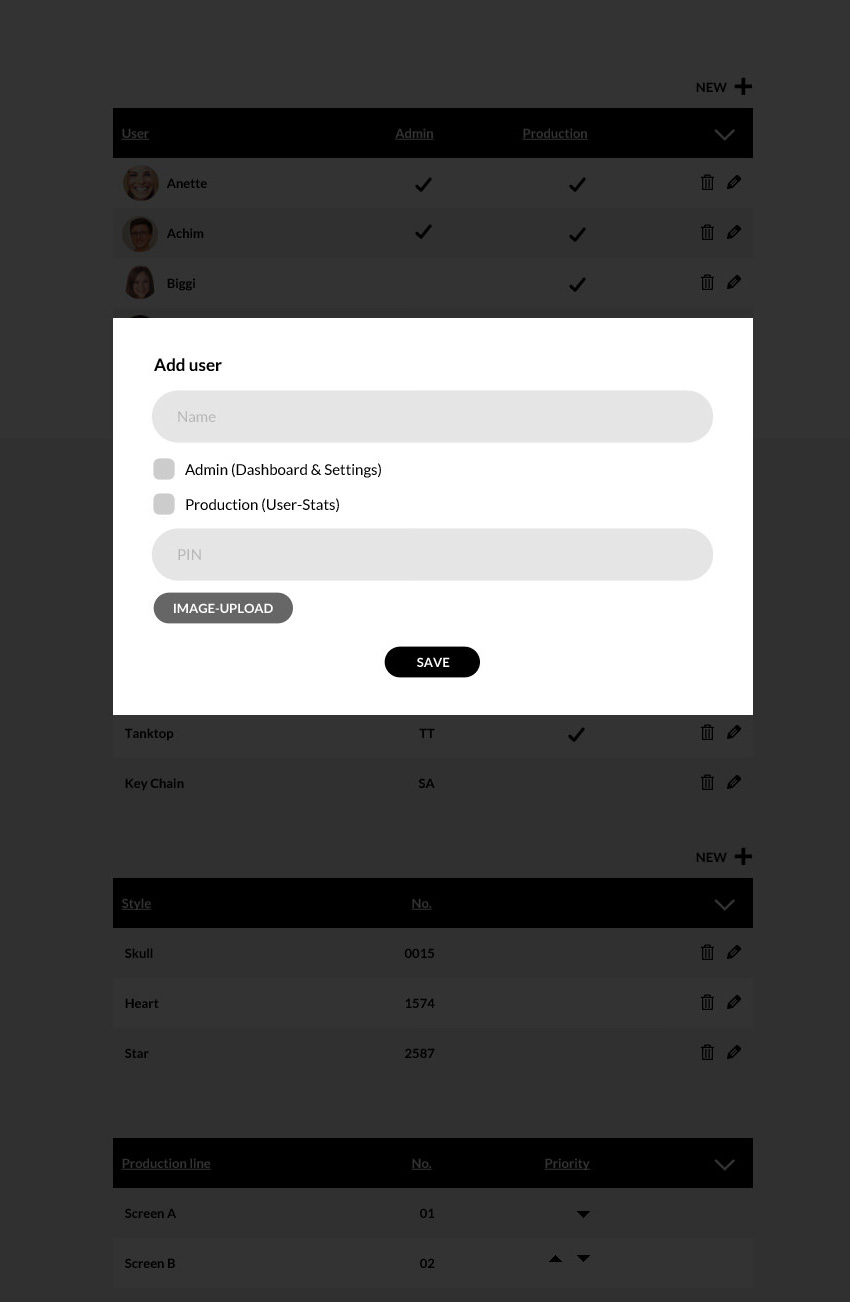

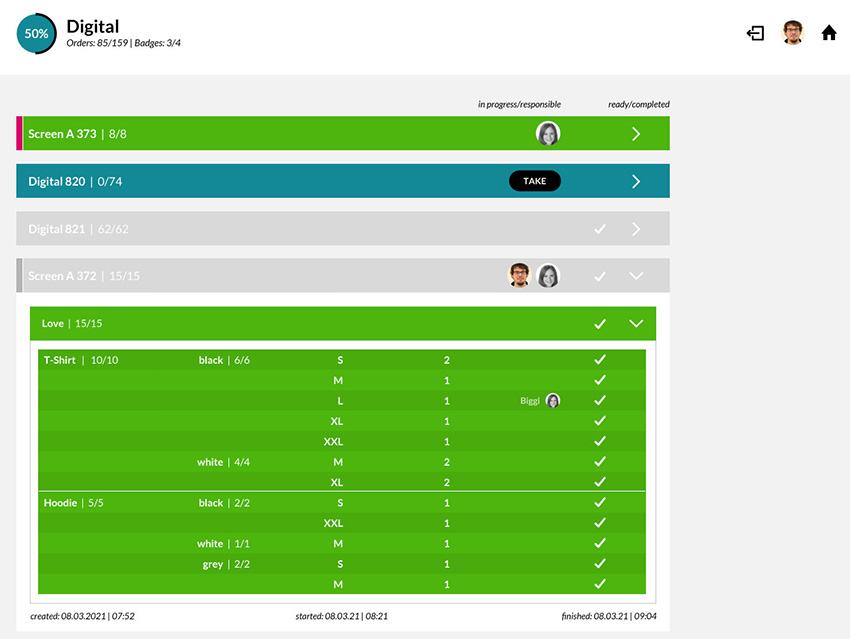

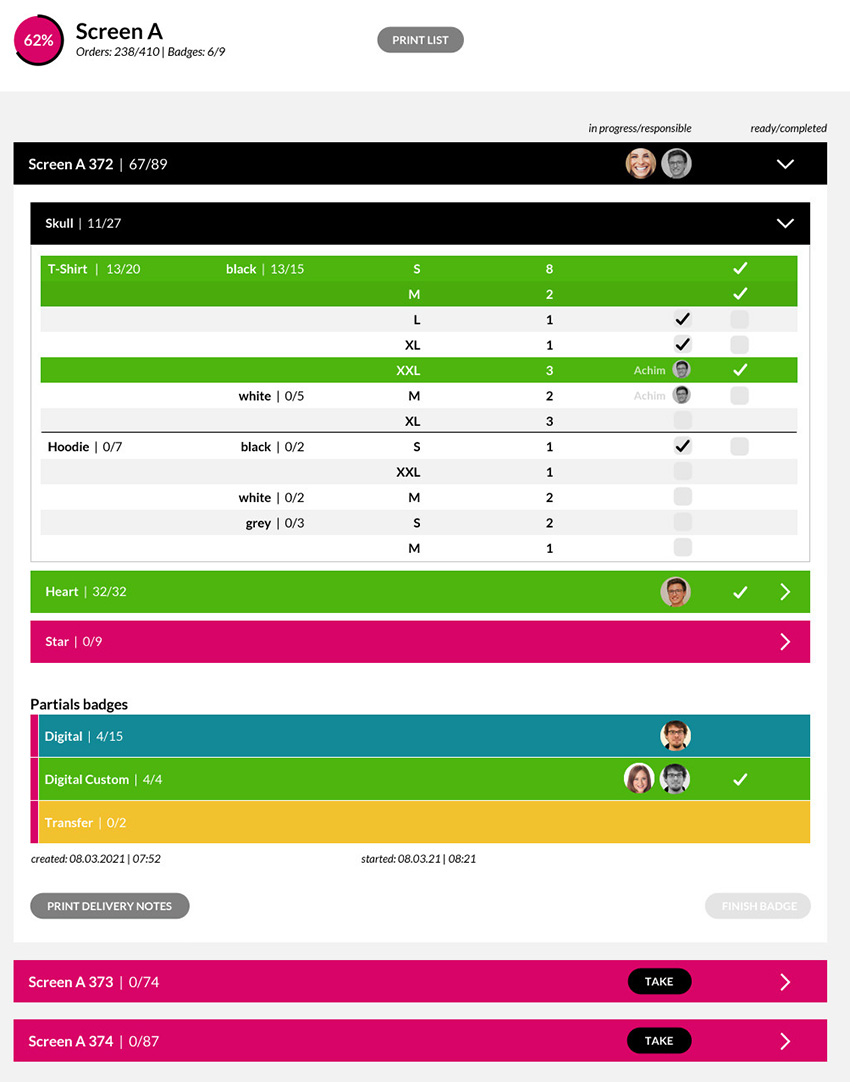

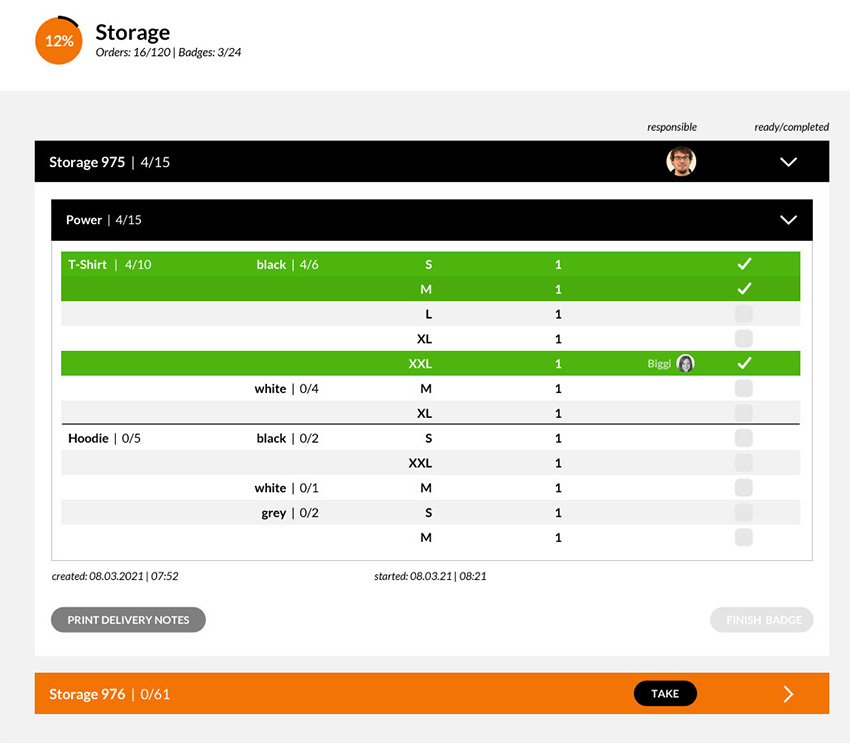

- as admin: controlling, planning & generating pick production lists and badges

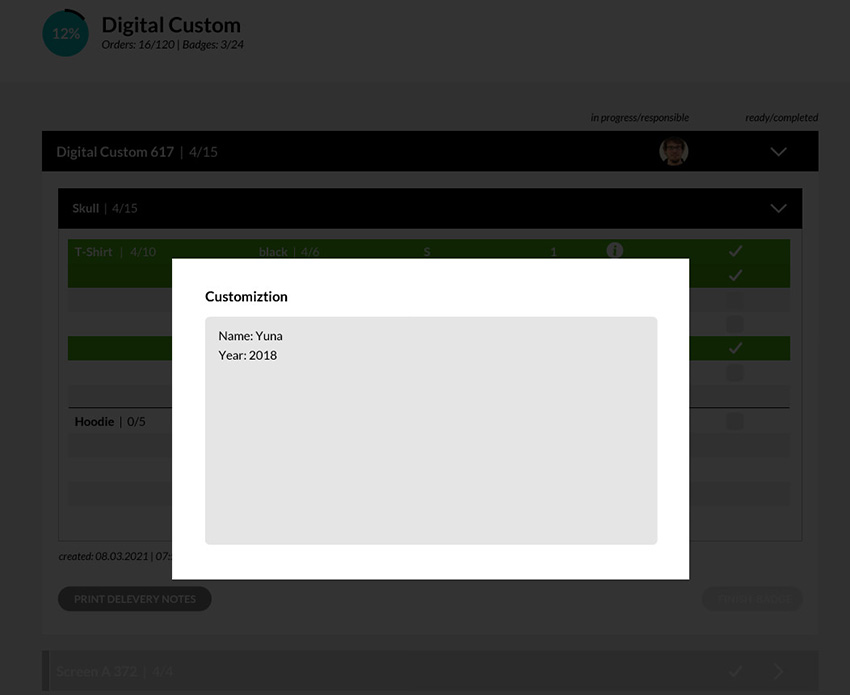

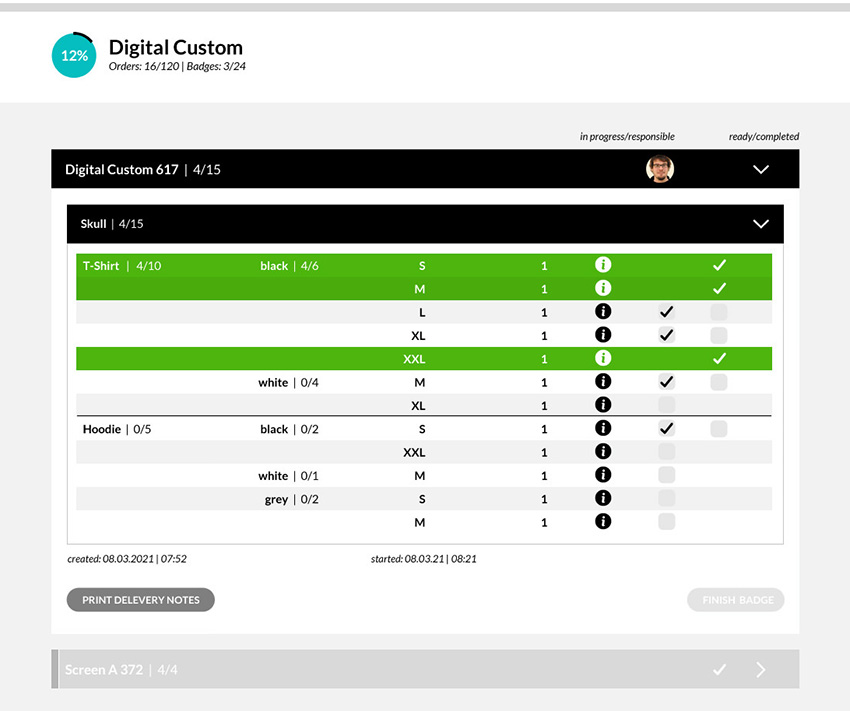

- on the production lines: view of the respective pick production lists on tablets + employee assignment + internal status ("in progress" & "finished") + printout of delivery notes > transfer of the finished goods to the packing tables

- at the packing tables: scanning the barcodes on the delivery notes > generating an order with DHL-API and then automatically printing a packaging-label > status change in Billbee + shipment number by email to the customer (send by Billbee)

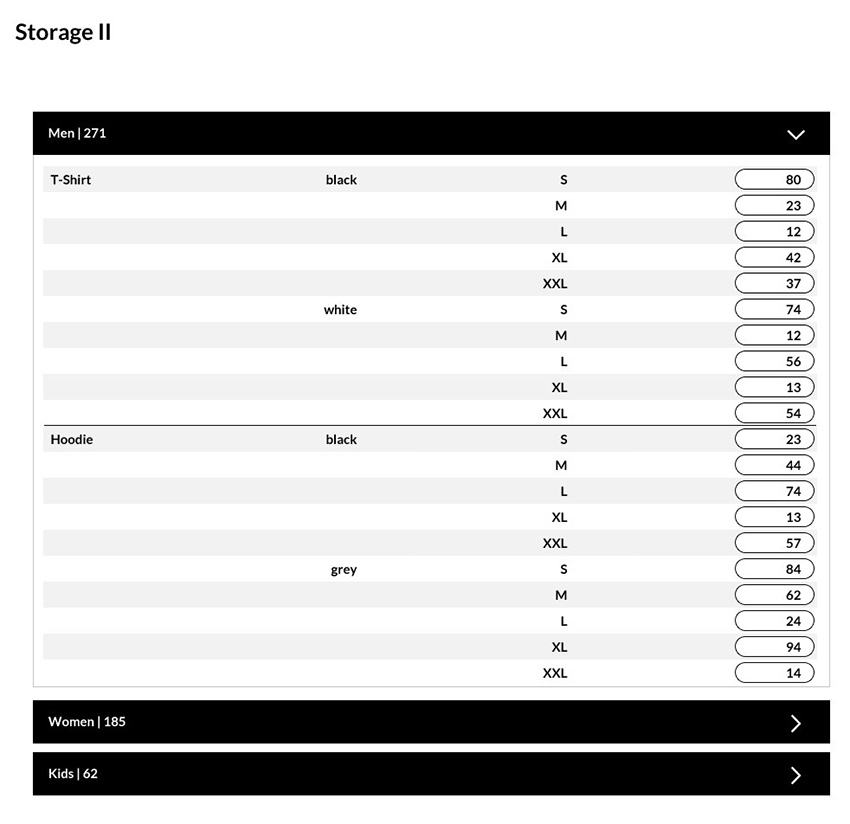

- Storage management of pre-produced goods

- Orders of largely printed textiles, which are largely produced "on demand" (i.e. only after an order) must be processed. There are raw materials / various basic products (like T-shirts, hoodies, pants) and they are printed with different motifs

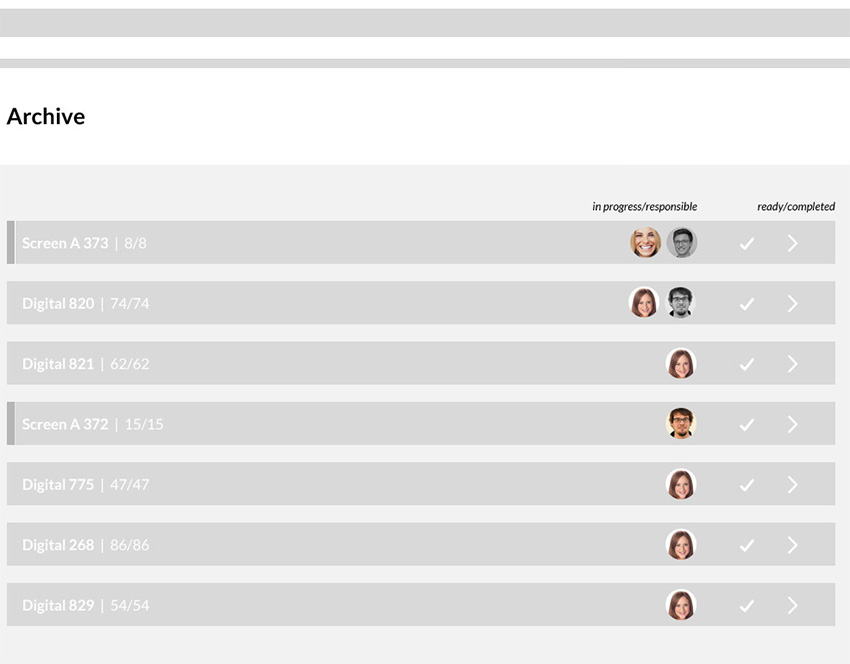

- The production takes place using different printing processes (screen print, digital print or transfer print), for each printing process there is one or – at “Screen print“ & “Digital print“, two production lines - on which the goods are produced. “production line“ = “printing process“

Automation –

- The camera of the device can be used to scan the barcode > gets the data from Billbee (ERP) > place an order at DHL > gets the shipping label and send it to the printer

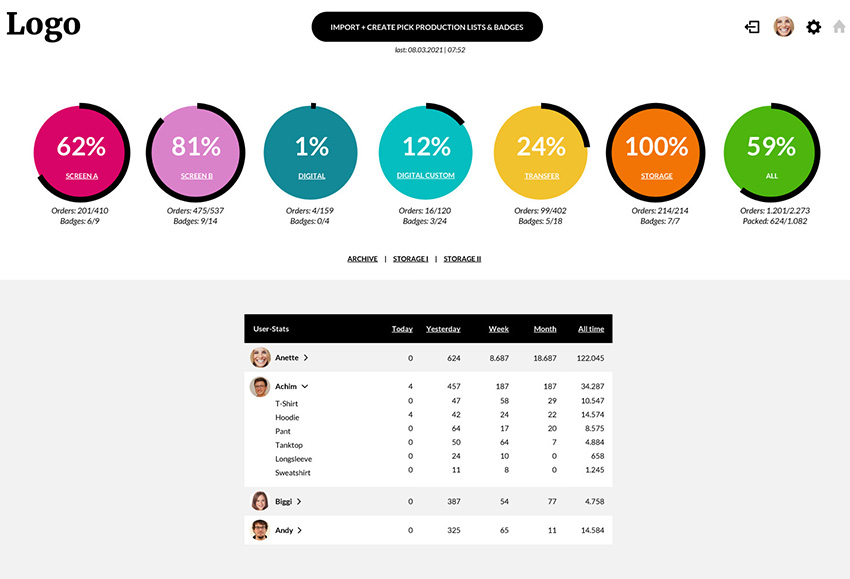

- All statuses (assignment of the pick production list & employees, "in progress", "finished") are displayed on the admin dashboard and on all devices as a live status display (is dynamically / via AJAX reloaded / Real-time synchronized on all devices)!

- The batches are displayed in gray on the picking & production list 24 hours (after the batch has been "completed")

- The employee statistics are always reset at 00:00, i.e. the data from "today" are output > "yesterday" and "today" everything is set to zero

Client’s need this solution because there is an individual production process with some individual requirements (which classic ERP or merchandise management systems can usually not map) a custom solution makes sense here.

Solution

After a formal tender and selection process, RWS engaged three developers and one project manager. Project manager develop the screens and provide the project outline. Our developer communicate with Billbee ERP via API get the order data and prepare the admin dashboard.

We use Laravel – PHP framework to create the complete web application. The database is in MySQL. We create the database schema first with coordinates with client. We translated the sophisticated data feed from the ERP into intuitive web and mobile dashboard. In general, we complete this project communicating via Billbee ERP API. In it major tasks, we take data from ERP, store in process in database, user logged in and complete their order, print DHL shipping label and update order Status in ERP.

Using Laravel web sockets , pusher server and Laravel Mix with Node JS, our team achieved the real time synchronize, and seamless communication via web application between order process people. We connect google drive file system using Laravel frame work to get the order invoice that is store on google drive From ERP solution. The multiple (in a process) PDF invoice merge in a single invoice and send to print.

Raghwendra Web Services had wide experience of creating dashboards for use in a wide range of industries, including ecommerce, education and healthcare.